About us

Kemiplast S.R.L

Via A. Volta 11, 50041,

Calenzano (Firenze), Italy

- Coextruded Film

- Vacuum film

- Laminated film

- Antifog film

- Aroma barrier film

- Metallized Film

Technology

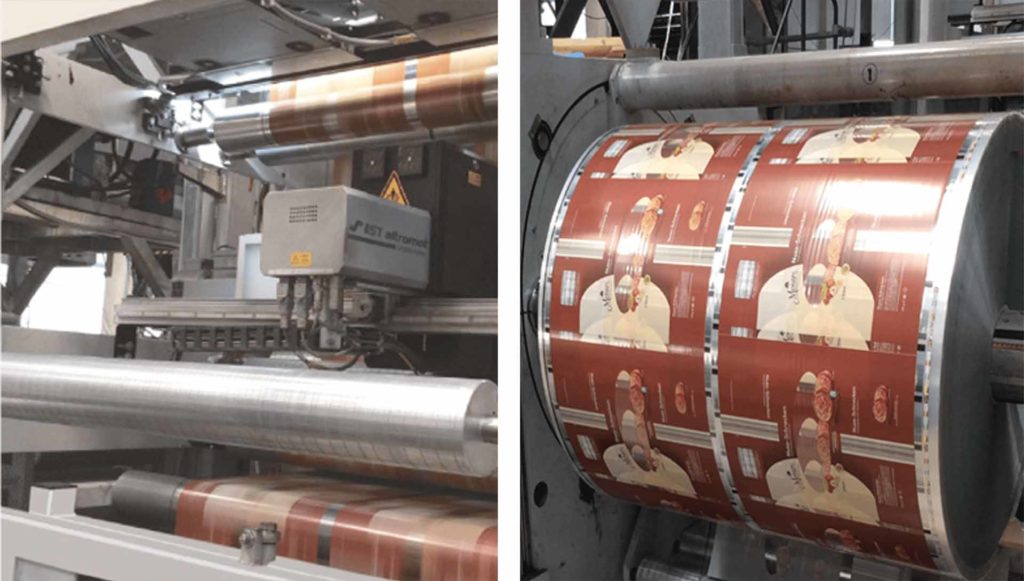

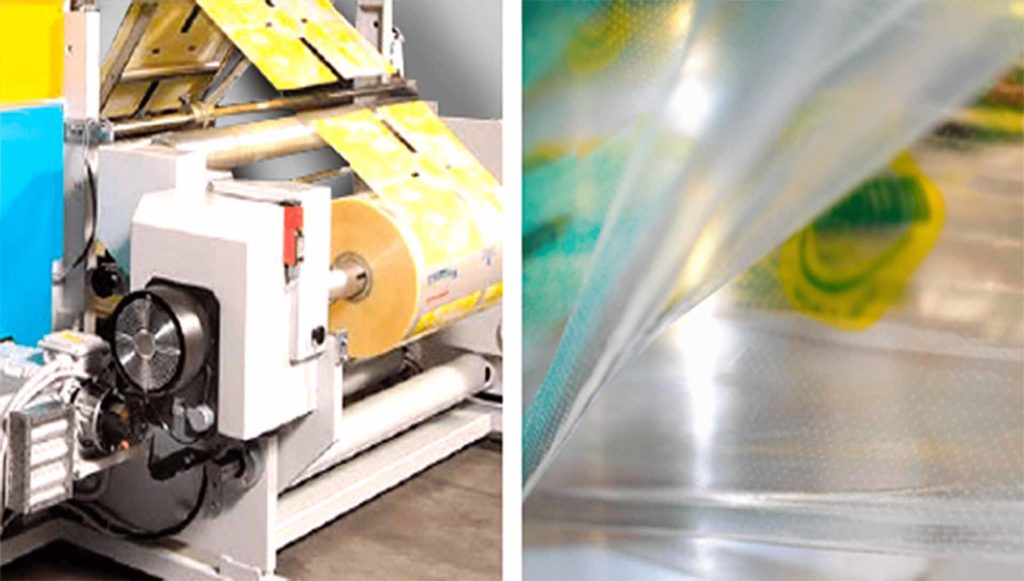

Kemiplast has a great machine park: our flexographic print machines, solventless (up to four layers) laminating machines, hot needle microperforation and macroperforation machinery allow us to guarantee a constant quality at the highest levels.

All production phases are controlled by experts with a consolidated experience, who constantly update their knowledge and skills.

Therefore our Technical Office is ready to fulfil all your information needs.

If you want to know more about our technologies, products and available packaging solutions, please contact us directly at – info@kemiplast.com

We have a Graphic Department that works together with costumers in order to establish what requirements have to be met

Thanks to our newest printing technology, together with the advanced systems for controlling printing operations and colours, Kemiplast offers high flexographic printing quality up to eight colours.

The intensity of rotogravure printing is given by the fact that the ink is taken directly from the support.

Kemiplast delivers optimal solution designed to meet the real customers’ needs thanks to the combination of various film structures

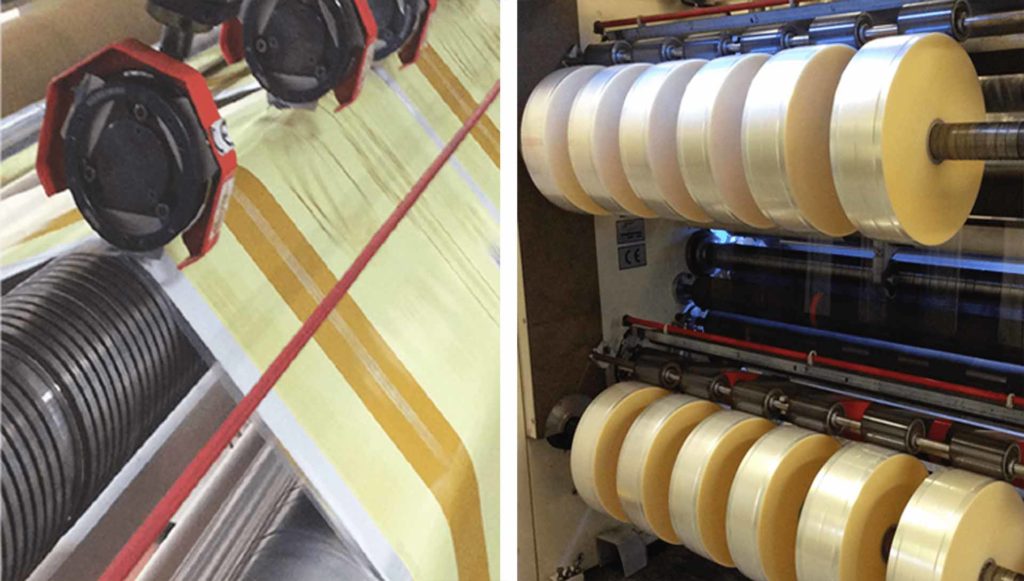

SLitter Department composed of a battery of slitters equipped with the most modern control systems.

Paper packaging with windows allows the customer to admire the products purchased and maintain their integrity.

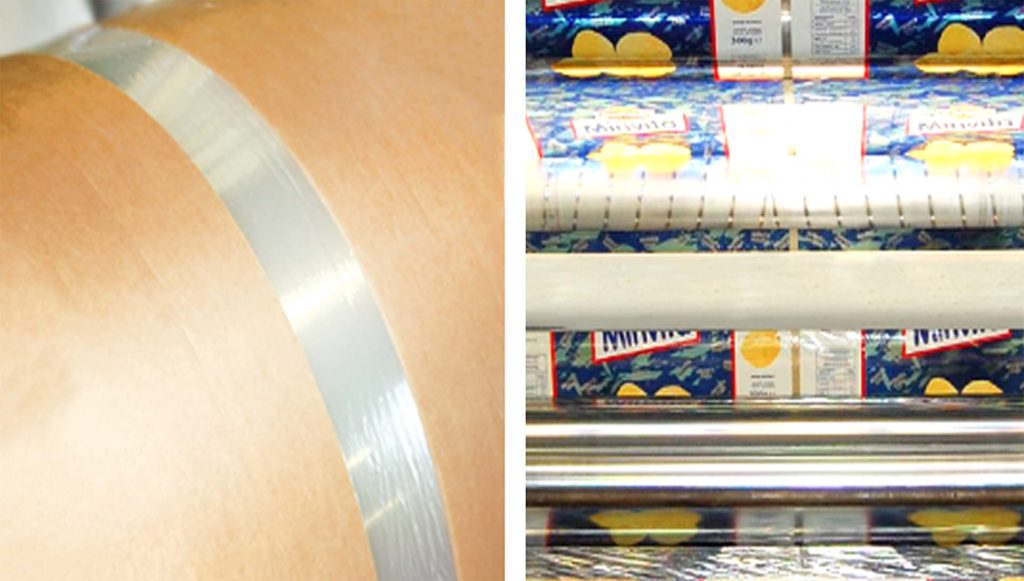

Cold seal technology welds without heat, using only the pressure where it is required.

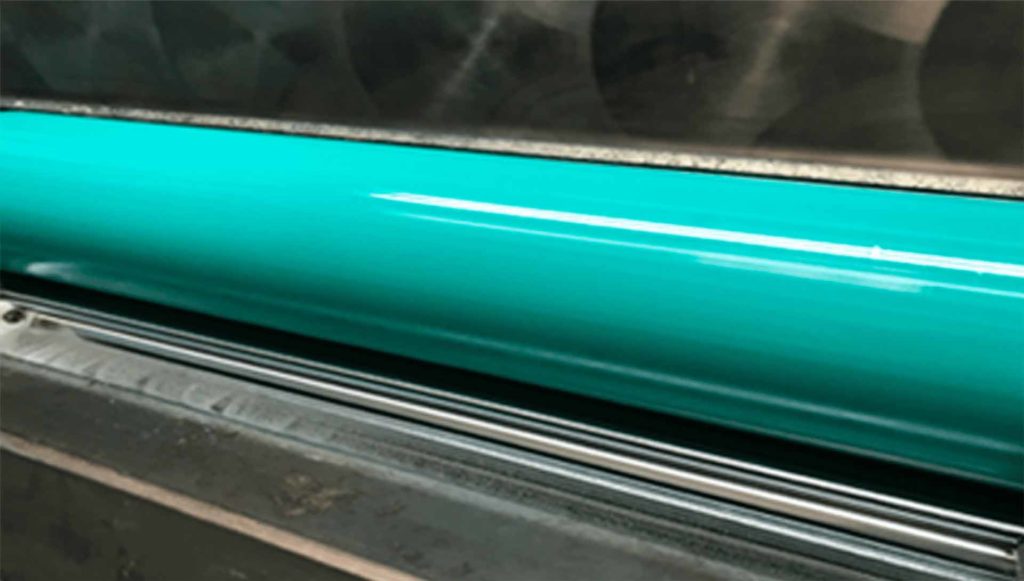

Kemiplast has a technologically advanced system that is able go realize many kind of varnishes

Thanks to the metallization process, that consists in the deposition of metal in low pressure condition above the film, we can obtain film both with aesthetic and functional properties (OXYGEN, LIGHT AND AROMA BARRIER PROPERTIES)

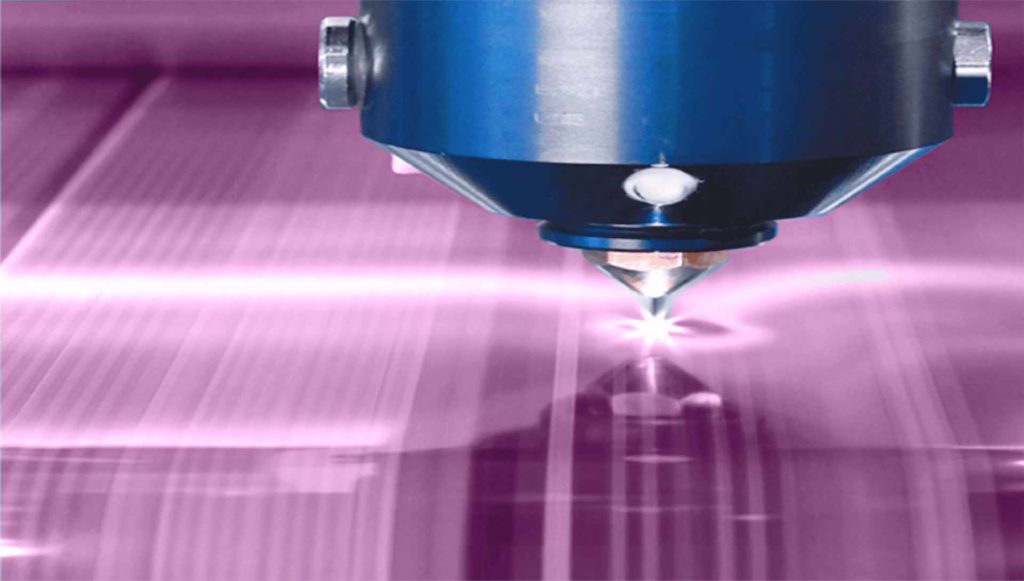

We are able to extend the shelf life of the products offering a wide range of very high perforations precision.

Packaging always in step with the times that offer inserting with easy opening

Kemiplast produces macroperforated films for specific applications that require a modulated release of humidity and atmosphere regulation

We produce bags with various types of paper for a wide range of applications.

Kemiplast has a Centre Folded Rolls Production Deparment that guarantees a rapid and flexible execution of the orders.

We produce bags with side and bottom sealing that allow us to cover a wide range of applications.

Kemiplast S.R.L

Via A. Volta 11, 50041,

Calenzano (Firenze), Italy